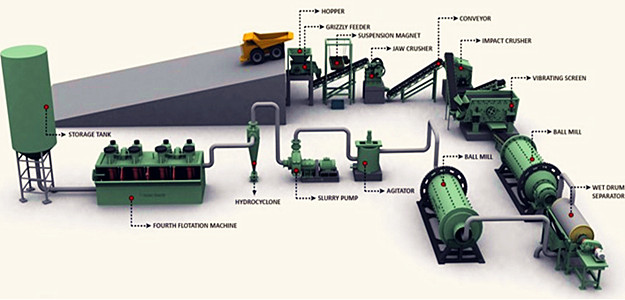

Gold Ore Processing Plant For Sale

KEFID gold ore processing plant has proven to be a versatile tool that exhibits many advantages over traditional gold ore crusher, They have been widely used in Ghana, Congo, South Africa, Chile, Peru, etc.

Gold ore crusher can process gold ore with dimension as wide as 200mm and the outsize is smaller than 10mm. According to the crushing stage, KEFID gold ore crushers are divided into three kinds: primary crusher, secondary crusher and tertiary crusher.

Gold ore grinding mill is capable of handling feed sizes up to 6 mm and grinding to products less than 20 microns, and has standard mill sizes ranging from 15HP (11kW) to 3000HP (2240 kW). KEFID gold mill includes trapezium mill, ball mill, coarse powder mill, high pressure mill and vertical mill, etc.

Gold ore screening plant works during the whole gold ore processing flow from crushing, grinding to concentration process. KEFID gold ore screening plant is featured with simple structure, long service time, high screening ratio and high efficiency.