Mineral Beneficiation Plant

Mineral Ore Dressing Process

Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, lead-zinc deposit, etc. For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore process. Equipment used in the whole plant are also with small capacity. As one of our Ghana customer, who has a gold ore mine and the gold ore dressing plant is of 10 ton per hour. We recommend to him with our small jaw crusher, small beneficiation machines. But different equipment can choose for different mineral ore processing, Kefid engineer team can give you whole support on various mineral ore deep processing flow desing and equipment choice.

Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, lead-zinc deposit, etc. For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore process. Equipment used in the whole plant are also with small capacity. As one of our Ghana customer, who has a gold ore mine and the gold ore dressing plant is of 10 ton per hour. We recommend to him with our small jaw crusher, small beneficiation machines. But different equipment can choose for different mineral ore processing, Kefid engineer team can give you whole support on various mineral ore deep processing flow desing and equipment choice.

Mineral Ore Beneficiation Methods

Beneficiation means the following asapplied to iron ore: milling (crushing and grinding), washing, filtration, sorting, sizing, gravity concentration, magnetic separation, flotation and agglomeration (pelletizing, sintering, briquetting, or nodulizing). Although the literature suggests that all these methods have been used to beneficiate iron ore, information provided by members of the American Iron Ore Association indicates that milling and magnetic separation are the most common methods used. Gravity concentration is seldom used at existing U.S. facilities. Flotation is primarily used to upgrade concentrates from magnetic separation by reducing the silica content of the concentrate.

Beneficiation flow design and equipment option

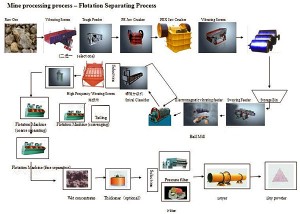

In general, beneficiation production line consists of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator and dryer and other major equipment, with feeder, hoist, conveyors can be composed of complete processing production line. The production line has the advantages of high efficiency, low energy, high handling capacity, economic rationality.

In general, beneficiation production line consists of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, concentrator and dryer and other major equipment, with feeder, hoist, conveyors can be composed of complete processing production line. The production line has the advantages of high efficiency, low energy, high handling capacity, economic rationality.

The beneficiation process production process is as follows: first jaw crusher, ore mined preliminary broken, broken to a reasonable degree of fineness via elevator, feeder evenly into the ball mill, ball mill ore crushing, grinding.