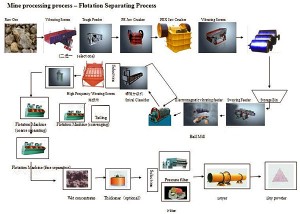

Chrome Ore Mining Process Plant

Chrome ore deposits are mined by both underground and surface techniques. most chrome ore must be processed by the chrome ore processing plants. the mainly chrome ore beneficiation method is gravity separation.

Process Introduction

- Large raw chrome ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will transferred to cone crusher by belt conveyor for secondary crushing; the crushed chrome ore stone will then transferred to vibrating screen for classifying. After classifying, the parts whose size below the mesh size will be transferred away as final products, while the other parts will return to cone crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

- The smaller crushed chrome ore is fed to ball mill for grinding. Inside the ball mill, the crushed chrome ore will grind the ore to about 0.2 mm with 3-inch steel balls.

- Screened products are transported to the jig for rough separation and to three concentrating tables for fine separation. Then, tailings are delivered into the jig in the next stage for screening for 4 times like this. All tailings int he concentrating table are sent to tailings reservoir after tailings dry stacking.

Please leave your message here! We will send detail technical info and quotation to you!