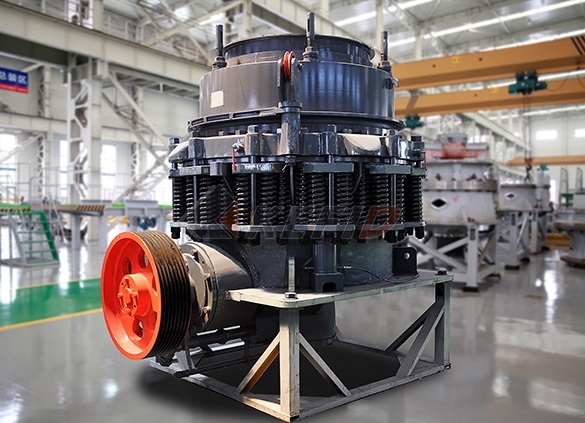

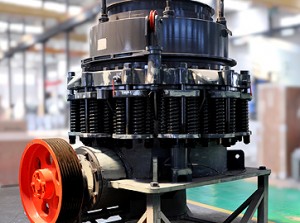

CS Cone Crusher How Much

CS Cone Crusher can be used for secondary and fine crushing of hard and medium hard mineral stone, such as iron ore, copper ore, quartz, granite, basalt and dolerite, etc.

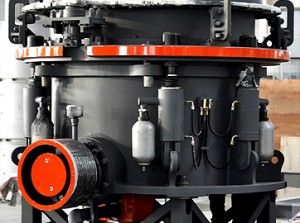

Cone Crusher Features:

1. the standard type is applied to secondary crushing;

2. the medium type is applied to fine crushing;

3. the short head is applied to super fine crushing.

It have follow types:

- 1. CS 75 (3′), capacity range from 30 to 180 ton per hour

- 2. CS160 (4 1/4′), capacity range from 100 to 350 ton per hour

- 3. CS240 (5 1/2′), capacity range from 180 to 600 ton per hour

- 4. CS400 (7′), capacity range from 380 to 1000 ton per hour