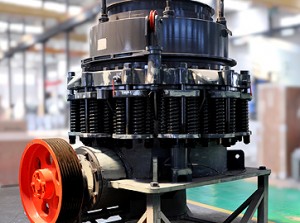

Cone Crusher

Cone crushers are the important crushing machines in stone crushing industry. China Kefid company is a leading manufactuer in cone crusher design and making with over 20 years experience. We have four types cone crusher: CS Cone Crusher, HST Cone Crusher, HPT Cone Crusher and Spring Cone Crusher, which are widely used to crush various mineral stones and bulk materials to medium size.

CS Cone Crusher

CS cone crusher is a kind of high efficiency spring cone crusher, which integrate optimization of cavity-type and reasonable stoke and advanced technology, and follows the conception of laminated crushing principle of more crushing and less grinding. CS Cone Crusher made plaster stone and engine oil separated, assured reliable performance. The type of crushing chamber depend upon the size of feed and fineness of the crushed product.

CS cone crusher is a kind of high efficiency spring cone crusher, which integrate optimization of cavity-type and reasonable stoke and advanced technology, and follows the conception of laminated crushing principle of more crushing and less grinding. CS Cone Crusher made plaster stone and engine oil separated, assured reliable performance. The type of crushing chamber depend upon the size of feed and fineness of the crushed product.

(Mm to inch conversion: 25.4millimeters=1 inch)

| Model | Dia. mm (inch) | Cavity | Feed Opening | Outlet Setting (mm) | Shaft Speed (r/min) | Power (kw) | Capacity (t/h) | Weight (t) | Dimension (mm) | |

| Closing Side (mm) | Open Side (mm) | |||||||||

| CSB75 | 900 (3′) | Fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 15 | 2821×1880×2164 |

| Coarse | 159 | 175 | 13-38 | 59-163 | ||||||

| CSB160 | 1295 (4 1/4′) | Fine | 109 | 137 | 13-31 | 485 | 185 | 109-181 | 27 | 2800×2342×2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | ||||||

| Coarse | 216 | 241 | 19-51 | 172-349 | ||||||

| CSB240 | 1650 (5 1/2′) | Fine | 188 | 209 | 16-38 | 485 | 240 | 181-327 | 55 | 3911×2870×3771 |

| Medium | 213 | 241 | 22-51 | 258-417 | ||||||

| Coarse | 241 | 268 | 25-64 | 299-635 | ||||||

| CSB315 | 2134 (7′) | Fine | 253 | 278 | 19-38 | 435 | 315 | 381-726 | 110 | 4613×3251×4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | ||||||

| Coarse | 334 | 369 | 31-64 | 789-1270 | ||||||

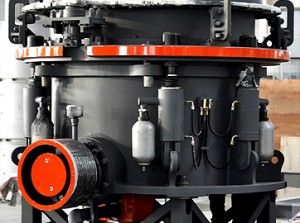

HPT Cone Crusher

HPT Cone Crusher is designed to meet clents’s request of the high outputs, excellence product fineness and economical running costs. HPT cone crusher introduced the germany technology, not only improves the production capacity and crushing efficiency, but also widens applying area, hardness range of materials from limestone to basalt. HPT cone crusher is an ideal crusher for large stone crushing factory and mining industry.

HPT Cone Crusher is designed to meet clents’s request of the high outputs, excellence product fineness and economical running costs. HPT cone crusher introduced the germany technology, not only improves the production capacity and crushing efficiency, but also widens applying area, hardness range of materials from limestone to basalt. HPT cone crusher is an ideal crusher for large stone crushing factory and mining industry.

(Mm to inch conversion: 25.4millimeters=1 inch)

| Type | Cavity (coarse/fine) |

Min. discharge size (mm) |

Feed size (mm) |

Capacity (t/h) | Power (kW) |

Weight (t) |

movable cone diameter (mm) |

| HPT-200 | C | 13 | 150 | 120-240 | 160 | 13 | 950 |

| F | 6 | 76 | 55-180 | ||||

| HPT-300 | C | 20 | 240 | 190-380 | 250 | 18 | 1160 |

| F | 13 | 145 | 110-260 | ||||

| HPT-400 | C | 13 | 290 | 190-610 | 315 | 26 | 1400 |

| F | 30 | 100 | 108-320 | ||||

| HPT-500 | C | 16 | 320 | 380-700 | 400 | 33 | 1500 |