Kefid VSI Crusher has bright prospect in Oman

Oman has always been regarded as a key market in the Middle East market by us. So, we have accumulated a lot of Oman customers. We keep in touch with each other very often. We just get a good information from them through our regular communication.

Oman is a mountainous country, so there are a lot of quarries. Quarrying starts early here, the stones are generally granite and limestone, which are mainly from mountain blasting and dry river bed mining. For the moment, there’s a big problem confuses them most. They have many small stones which are 5-20 don’t know how to deal with them, because the stones they got from the dry river bed are generally divided into: 0-2mm, 2-5mm, 5-20mm, 20-200mm, and over 200mm.For the 0-2mm,2-5mm stone, they can be used as natural sand or for brick making directly, and the 20-200mm stone can be crushed by the impact crusher or cone crusher, while, the stones which are 5-20mm neither can be crushed by secondary crusher nor be sold as sand directly because its round grain shape not suitable for use in concrete or pavement construction. And as the transportation fee is high, so they have to put them nearby. It’s common scene in Oman that these small stones accumulated near the stone factories.

Oman is a mountainous country, so there are a lot of quarries. Quarrying starts early here, the stones are generally granite and limestone, which are mainly from mountain blasting and dry river bed mining. For the moment, there’s a big problem confuses them most. They have many small stones which are 5-20 don’t know how to deal with them, because the stones they got from the dry river bed are generally divided into: 0-2mm, 2-5mm, 5-20mm, 20-200mm, and over 200mm.For the 0-2mm,2-5mm stone, they can be used as natural sand or for brick making directly, and the 20-200mm stone can be crushed by the impact crusher or cone crusher, while, the stones which are 5-20mm neither can be crushed by secondary crusher nor be sold as sand directly because its round grain shape not suitable for use in concrete or pavement construction. And as the transportation fee is high, so they have to put them nearby. It’s common scene in Oman that these small stones accumulated near the stone factories.

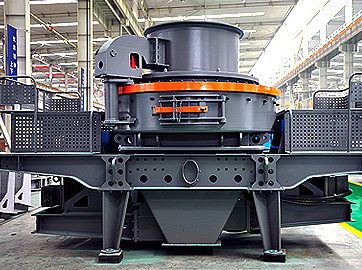

After hearing this, we just make a plan for them specially. According to their specific situation, our VSI crusher is perfect for the stones 2-20 mm. Our VSI crusher or called sand making machine is a newly researched equipment, with international advanced level, it’s widely used for artificial sand, more suitable for crushing materials of middle hardness and high hardness, such as the granite and limestone. This machine is easy to be operated, low cost and low consumption, the sand it makes are of fine grain size. So, it is only fitting for them. We just find a new business opportunity this time, it’s true to say that few people using VSI crushers there, since Kefid brand has a good reputation in Oman, so I believe that it will be successful for us to develop our VSI crusher market there. Because Kefid insists that customer first, we always stand on the customers’ side to solve their problems.

After hearing this, we just make a plan for them specially. According to their specific situation, our VSI crusher is perfect for the stones 2-20 mm. Our VSI crusher or called sand making machine is a newly researched equipment, with international advanced level, it’s widely used for artificial sand, more suitable for crushing materials of middle hardness and high hardness, such as the granite and limestone. This machine is easy to be operated, low cost and low consumption, the sand it makes are of fine grain size. So, it is only fitting for them. We just find a new business opportunity this time, it’s true to say that few people using VSI crushers there, since Kefid brand has a good reputation in Oman, so I believe that it will be successful for us to develop our VSI crusher market there. Because Kefid insists that customer first, we always stand on the customers’ side to solve their problems.

If VSI can be widely used there, it will not only solve the problem of surrounding stones, but also will bring profits to them.