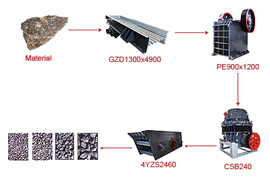

150-200 TPH STONE CRUSHING PLANT

This crushing plant is used to crush hard stone (like: Granite, basalt, river stone, etc.) from <630mm down to about 0-5, 5-10, 10-20, 20-40mm (or other sizes according to your need) as aggregate for construction. Kefid can provide you the well-shaped cubic final products, with low energy consumption, low cost, easy maintenance, and high efficiency.

This crushing plant is used to crush hard stone (like: Granite, basalt, river stone, etc.) from <630mm down to about 0-5, 5-10, 10-20, 20-40mm (or other sizes according to your need) as aggregate for construction. Kefid can provide you the well-shaped cubic final products, with low energy consumption, low cost, easy maintenance, and high efficiency.

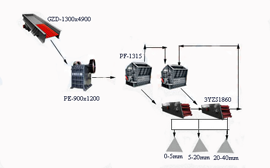

Raw material under 630mm is fed into primary jaw crusher PE750*1060 via vibrating feeder GZD1100*4200. Wastes screened out by grizzly bar on the vibrating feeder and be transported to designated place via belt conveyor.

Stuff from jaw crusher PE750*1060 is transported to stock pile via belt conveyor.

Stuff from stock pile is fed into secondary cone crusher CSB160(c) via feeder GZG80-4 and belt conveyor.

Stuff from cone crusher CSB160(c) is fed into vibrating screen 4YZS1860 via belt conveyor.

After screening, eligible stuff is transported to final products pile via belt conveyor.

Ineligible stuff is transported to cone crusher CSB160(c) for recrushing.

| NO. | Equipment | Model | Max. Feeding Size (mm) | Motor(KW) | Number |

| I | Vibrating Feeder | GZD1100X4200 | 600 | 15 | 1 |

| II | Jaw Crusher | PE750×1060 | 630 | 110 | 1 |

| III | Vibrating Feeder | GZG80-4 | 1 | ||

| Ⅳ | Cone Crusher | CSB160 | 1295 (4 1/4′)Dia. mm (feet) | 185 | 1 |

| V | Vibrating Screen | 4YZS1860 | 100 | 30 | 1 |

| Belt:B500×10m, B1000×20m, B1000×32m, B1000×26m, B650×27m, B500×15m, B500×15m, B650×15m, B650×15m | |||||